Passivehouse Heating and Ventilation

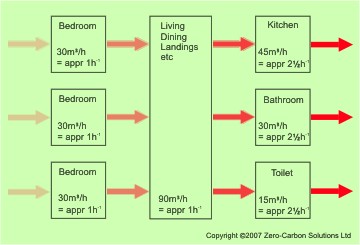

In an airtight building the ventilation system becomes a vital component, and this is a main factor determining the workflow in passivehouse design. To be successful it requires close cooperation between building technicians and architect from day one. The method whereby an architect designs a house and the builders and traders simply fit installations within this envelope does not work in the case of passivehouses. The reason is that air needs to be transported through a passivehouse according to a specific, albeit not completely rigid, pattern. Providing comfortable and safe air requires the supply of 20-30m2h-1 for each person. Furthermore, the role of the ventilation system is to remove harmful and noxious elements, e.g. released by unsuitable materials used in furniture production, as well as excess humidity, especially from bathrooms and kitchens. Because there are few leaks in the building envelope the ventilation system needs to be balanced as illustrated in the figure below.

The consequence of this requirement is that the room layout and room sizes need to be coordinated to support this principle. These calculations actually need to be carried out and the sums add up. One way to accomplish this is to lead separate ventilation ducts into each individual room and control the air flow through each room by means of motorised valves. However, this is obviously not normally an economic solution. Instead you induce fresh air into certain zones of the dwelling, e.g. the bedrooms, let the air overflow through living and dining rooms, corridors, etc, in order to lead it through the rooms requiring the highest ventilation rates, i.e. kitchen, baths, toilets, airing cupboards, etc, before expelling it.

Normally even balanced ventilation system are furnished with some means of manual regulation, which can temporarily boost their performance, e.g. in case of smoking in the house.

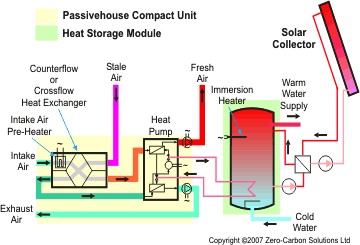

The illustration at the top of the page illustrates a typical installation covering passivehouse ventilation and heating. It is necessary to keep the outside air reaching the heat exchanger frost free. In cold climates this is normally accomplished by leading the air through a ground heat exchanger before it arrives at the heat exchanger. This is probably not necessary in a large part of the UK and Ireland but to be on the safe side a small electrical pre-heater whose only purpose is to keep the air temperature above a couple of degrees in case of outside frost has been included.

The intake air is subsequently heated in heat exchanger, typically a counterflow plate exchanger but some manufacturers use crossflow exchangers, by the stale air extracted from bathrooms, kitchen, etc. Even after this exchange there is often enough heat left in the stale air to profitably run a small air to air heat pump used to extract this heat and add it to the fresh air before this is distributed across the building. If this is not required the heat can instead be used to add heat to the heat storage.

The figure also shows a typical solar collector circuit contributing most of the warm water required. In this case an immersion heater has been included to cover any additional requirements. As evident from the figure there are various controls, normally controlled by a small computer whose input is provided by a few sensors that have not been included in the figure.